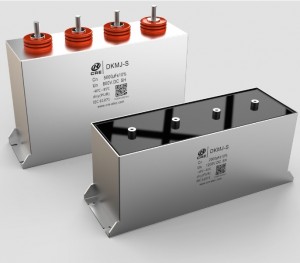

16V10000F super capacitor bank

Application

Ups system

Power tools, power toys

Solar system

Electric vehicle & hybrid electric vehicle

Backup power

Composition of energy storage module ,for example 16V,10000F

|

No |

Item |

Specification |

Qty |

Remark |

|

1 |

UnitSuper capacitor |

2.7V/60000F 60*138mm |

6PCS |

|

|

2 |

Connector |

/ |

1pcs |

|

|

3 |

Shell |

customsized |

1pcs |

|

|

4 |

Fender |

6 series |

1pcs |

Charge discharge mode

Standard charging method: set 1C (25A) charging current, constant current and constant voltage charging, cut-off current 0.01c (250mA), charging cut-off voltage 16V(DC), under the operating environment of 25℃±5℃.

Standard discharge mode: set 1C (25A) discharge current, constant discharge to cut-off voltage 9V(DC), under the operating environment of 25℃±5℃.

Basic features of the product,for example 16V,10000F

Test condition

A) ambient temperature: 25℃±3℃

B) relative humidity 25%-85%

C) atmospheric pressure: atmospheric pressure 86kpa-106kpa

Measuring instruments and equipment

All instruments and equipment (including test equipment and instruments for monitoring and monitoring test parameters) shall be checked or measured in accordance with the national metrological verification regulations or relevant standards, and within the validity period.All measuring instruments and equipment shall have sufficient accuracy and stability, the accuracy shall be one order of magnitude higher than the accuracy of the measured index or the error shall be less than one third of the allowable error of the measured parameter.

A) voltmeter: accuracy should be not less than 0.5 on the Richter scale, its internal resistance at least 1 k Ω/V.

B) ammeter: accuracy shall not be lower than 0.5 level;

C) thermometer: with an appropriate range, the dividing value shall not be greater than 1℃, and the calibration accuracy shall not be less than 0.5℃

D) timer: on time, minutes and seconds, with accuracy not less than ±1%;

E) measuring tools for measuring dimensions: the dividing value shall not be greater than 1mm;

F) measuring tools for weighing weight: accuracy not less than ±0.05%.

Reference standards

QC/ t741-2014 « automotive supercapacitor »

QC/ t743-2006 « lithium-ion capacitors for electric vehicles »

Electrical performance and safety performance

|

No |

Item |

Test mothod |

Test requirement |

Remark |

|

1 |

Standard charging mode | At room temperature, the product is charged at constant current of 1C. When the product voltage reaches the charging limit voltage of 16V, the product is charged at constant voltage until the charging current is less than 250mA. |

/ |

|

|

2 |

Standard discharge mode | At room temperature, the discharge will be stopped when the product voltage reaches the discharge limit voltage of 9V. |

/ |

|

|

3 |

Rated capacitance |

1. The product is charged according to the standard charging method. |

The product capacity shall be no less than 60000F |

|

| 2.Stay 10min。 | ||||

| 3.The product discharges according to the standard discharge mode. | ||||

|

4 |

Internal resistance |

Ac internal resistance tester tests, precision: 0.01 m Ω |

≦5mΩ |

|

|

5 |

Discharge of high temperature |

1. The product is charged according to the standard charging method. |

Discharge capacity should ≥ 95% rated capacity, product appearance without deformation, no burst. |

|

| 2. Put the product into the incubator of 60±2℃ for 2H. | ||||

| 3.Discharge the product according to the standard discharge mode, recording discharge capacity. | ||||

| 4.After the discharge, the product will be taken out under normal temperature for 2 hours, and then visual appearance. | ||||

|

6 |

Low temperature discharge |

1.The product is charged according to the standard charging method. |

放电容量应≧70%额定容量,产品外观无变形,无爆裂。 |

|

| 2.Put the product into the incubator of -30±2℃ for 2H. | ||||

| 3.Discharge the product according to the standard discharge, recording discharge capacity. | ||||

| 4.After the discharge, the product will be taken out under normal temperature for 2 hours, and then visual appearance. | ||||

|

7 |

Cycle life |

1.The product is charged according to the standard charging method. |

No less than 20,000 cycles |

|

| 2.Stay 10min。 | ||||

| 3.The product discharges according to the standard discharge mode. | ||||

| 4.Charge and discharge according to the above charging and discharging method for 20,000 cycles, until the discharge capacity is less than 80% of the initial capacity, the cycle is stopped. | ||||

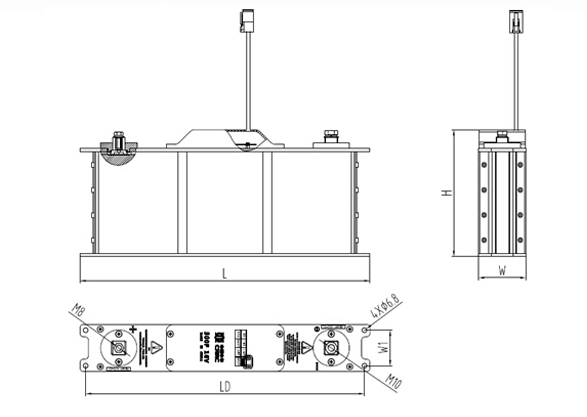

Outline drawing

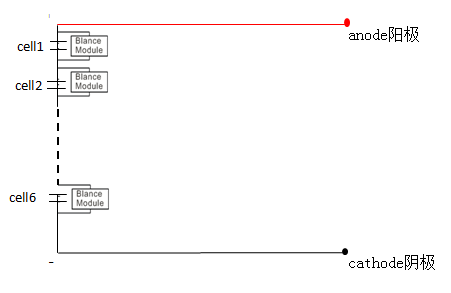

Circuit schematic diagram

Attention

1. The charging current shall not exceed the maximum charging current of this specification. Charging with a current value higher than the recommended value may cause problems in charging and discharging performance, mechanical performance, safety performance, etc. of the capacitor, resulting in heating or leakage.

2. The charging voltage shall not be higher than the rated voltage of 16V specified in this specification.

The charging voltage is higher than the rated voltage value, which may cause problems in the charging and discharging performance, mechanical performance and safety performance of the capacitor, resulting in heat or leakage.

3. The product must be charged at -30~60℃.

4. If the positive and negative poles of the module are connected correctly, reverse charging is strictly prohibited.

5. The discharge current shall not exceed the maximum discharge current specified in the specification.

6. The product must be discharged at -30~60℃.

7. Product voltage is lower than 9V, please do not force discharge;Full charge before use.

Transport

The energy storage module can be transported by any vehicle. During the loading and unloading process, it is prohibited to drop, roll and weigh.In the process of transportation should not be subjected to violent mechanical impact, exposure to the sun, rain.

Products should not be stored in places where humidity exceeds 80%, or where toxic gases are present.

It is best stored in a dry, ventilated environment away from fire, acidity or corrosiveness.