DC Link Capacitor

-

Inverter DC-link film capacitors in power conversion

1. Metal shell encapsulation, dry resin infusion;

2. Usable in harsh environment

3. High reliability

4. Self-healing ability

5. Film capacitors also have a longer life span than electrolytics capacitor etc.

-

DC bus Capacitors for IGBT-Based Converters in Traction Apparatus

DC bus capacitor DMJ-MC series

Metallized film capacitors are made of two metallized films with plastic film as the dielectric.

A very thin (~ 0.03 μm[2]) vacuum-deposited aluminum metallization is applied to one or both sides to serve as electrodes.

-

Compact design Hybrid & Electric Vehicle Capacitors

1. Plastic package, sealed with eco-fridendly epoxy resin, copper leads, customized dimension

2. Resistance to high voltage, self-healing metallized polypropylene film

3. Low ESR, high ripple current handling capability

4. Low ESR, effectively reduce the reverse voltage

5. Large capacity, compact structure

-

Self-healing film Power capacitor bank for rail traction

The Luxury DKMJ-S series are the updated-version of DKMJ-S .For this type ,we use aluminium checkered plate cover for better performance. If the capacitor will have separate installation, and exposed to a space,this one is recommended.

-

Pin terminal PCB capacior for high-frequency / high-current applications

The DMJ-PS series are designed with 2 or 4 pin leads , mount on PCB board. Compared to electrolytic capacitors , large capacity and long life make it popular now.

-

Advanced Metallized polypropylene film capacitor in high voltage power applications

CRE Polypropylene power film capacitors are frequently employed in high voltage power applications due to their high dielectric strength, low volumetric mass, and extremely low dielectric constant (tanδ). Our capacitors also experience low losses and, depending on application demands, can be made with either smooth or hazy surfaces.

-

Power Film Capacitor Design for Electric Vehicle

1. Plastic package, sealed with eco-fridendly epoxy resin, copper leads, customized dimension

2. Resistance to high voltage, self-healing metallized polypropylene film

3. Low ESR, high ripple current handling capability

4. Low ESR, effectively reduce the reverse voltage

5. Large capacity, compact structure

-

PCB mounted DC link film capacitor designed for PV inverter

1. Plastic shell encapsulation, dry resin infusion;

2. leads with pins, compact structure, easy installation ;

3. low ESL and ESR;

4. High pulse Current.

5. UL certified;

6. Max operating temperature: -40 ~ +105℃

-

High power new design film capacitors

The DC-link capacitor’s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current.

CRE DC link capacitor apply for dry type technology which ensure its high performance, safety operating, long lifespan etc.

-

High Performance Capacitor for Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs) (DKMJ-AP)

Capacitor Model: DKMJ-AP Series

Features:

1. Copper Flat Electrodes

2. Plastic Packaging Sealed with Dry Resin

3. Large Capacitance in Small Physical Size

4. Easy Installation

5. Resistance to High Voltage

6. Self-healing Capabilities

7. Low ESL and ESR

8. Capable of Operating under High Ripple Current

Applications:

Specialized for Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs)

-

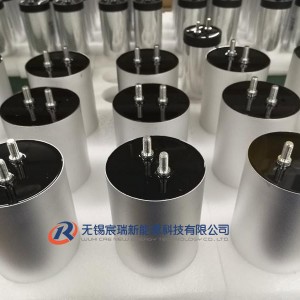

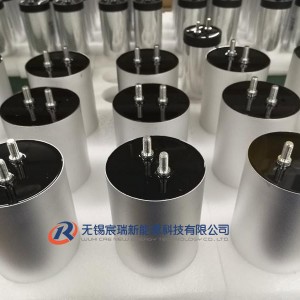

Newly Designed Power Electronic Capacitor with Self-healing Capability (DKMJ-S)

Capacitor Model: DKMJ-S

Features:

1. Copper nuts/screws electrodes, easy installation

2. Metallic packaging filled with dry resin

3. Large capacitance in small physical size

4. Resistance to high voltage with self-healing capability

5. Capability of operating under high ripple current

6. Longer Life Expectance and Better Performance Compared to Electrolytic Capacitors

Applications:

1. Energy Storage and Filtering in DC-Link Circuit

2. VSC-HVDC Applications based on IGBT (Voltage Sourced Converter) Transmitting Power Underground over Long Distance

3. Shore Power Supplies to Islands

4. Photovoltaic Inverter (PV), Wind Power Converter

5. Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs)

6. All Kinds of Frequency Converters and Inverters

7. SVG, SVC Energy Management Devices

-

Customized self-healing Film Capacitor for EV and HEV Applications

Advanced power film capacitors with controlled self-healing technology are one of the power electronics solutions that EV and HEV engineers can rely on to meet the stringent size, weight, performance, and zero-catastrophic-failure reliability criteria of this demanding market.

-

Power electronic film capacitor

CRE produces the following kinds of power electronic capacitors:

MKP metallized plastic film, compact, low-loss. All capacitors are self-healing, i.e. voltage breakdowns heal in a matter of microseconds and so produce no short circuit.

-

High current DC link film capacitor for electric drivetrain inverters

1. Plastic package, sealed with eco-fridendly epoxy resin, copper leads, customized dimension

2. Resistance to high voltage, self-healing metallized polypropylene film

3. Low ESR, high ripple current handling capability

4. Low ESR, effectively reduce the reverse voltage

5. Large capacity, compact structure

-

Metalized film capacitor for power supply application (DMJ-MC)

Power electronic film capacitors DMJ-MC series

Polypropylene film capacitors can qualify for high-class applications.

1. Very low dissipation factors (tan δ)

2. high quality factors (Q)

3. low inductance values (ESL)

4. No microphonics compared with ceramic capacitors

5. Metallized construction has self-healing properties

6. High rated voltages

7. High ripple current withstand